Unlocking Innovation with the Best Design Software 3D Printing Solutions

In the rapidly evolving world of additive manufacturing, design software 3d printing plays a pivotal role in transforming ideas into tangible, high-quality objects. From small startups to established manufacturing giants, leveraging sophisticated 3D design tools revolutionizes how products are conceptualized, developed, and produced. This comprehensive guide delves into the significance of design software 3d printing, outlining key features, benefits, and top solutions that drive business growth and innovation.

Introduction to Design Software 3D Printing

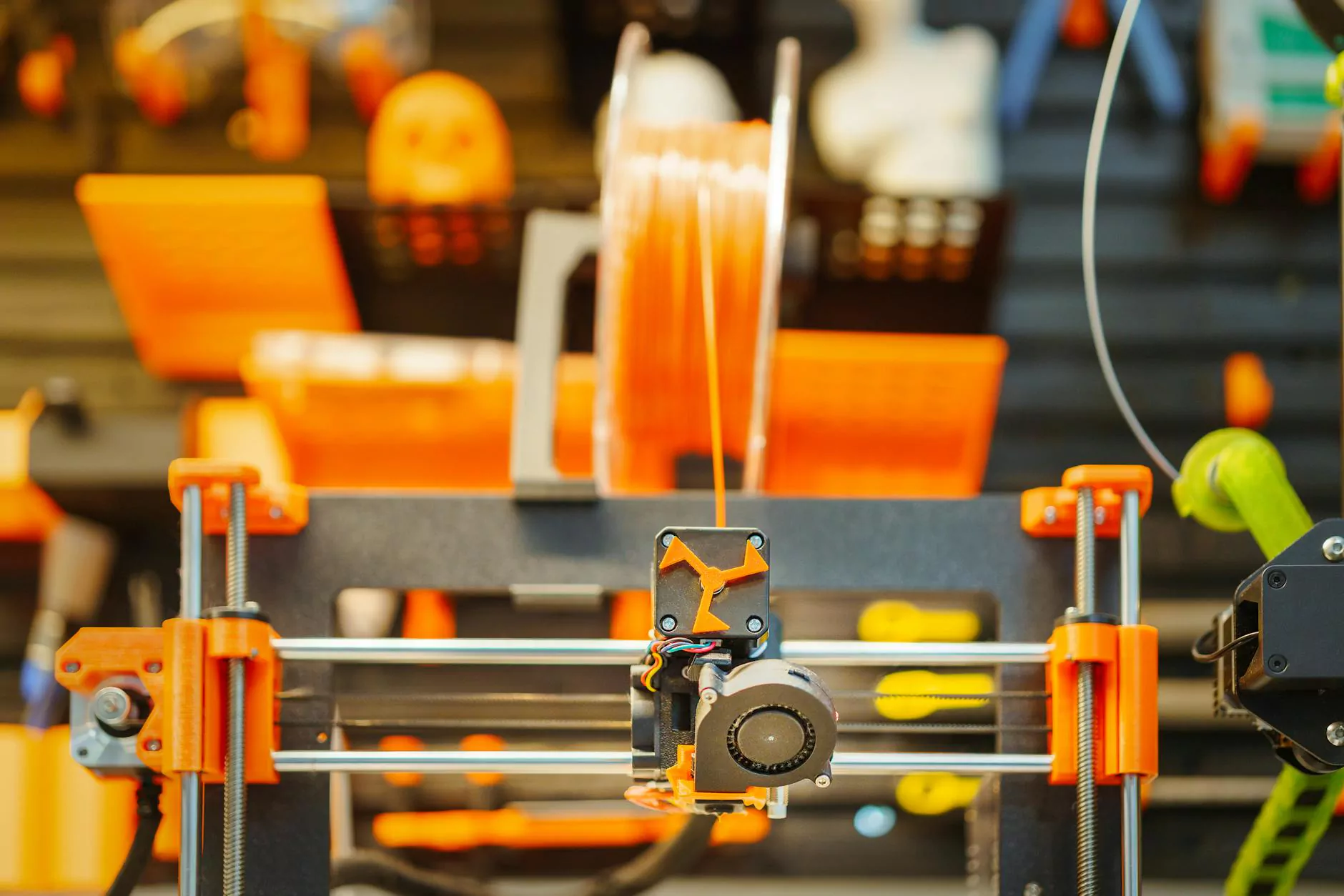

Design software 3D printing refers to specialized computer-aided design (CAD) applications tailored to facilitate the creation of 3D models optimized for additive manufacturing. Unlike generic CAD tools, these platforms incorporate features specifically designed to address the unique requirements of 3D printing processes, such as support structure generation, layer simulation, and filament flow analysis.

Utilizing the right design software 3d printing tools enables designers and engineers to produce complex geometries that traditional manufacturing methods cannot achieve. The seamless integration between design programs and 3D printers accelerates prototyping cycles, reduces material waste, and enhances the overall quality of final products.

The Critical Role of Design Software 3D Printing in Modern Business

Enhancing Creativity and Innovation

With advanced design software 3d printing, businesses can push the boundaries of creativity. These tools allow for the development of intricate designs featuring lightweight structures, organic shapes, and highly customized components, fostering innovation across industries such as aerospace, healthcare, automotive, and architecture.

Reducing Time-to-Market

Traditional manufacturing processes often involve lengthy lead times due to tooling and molds. In contrast, design software 3d printing enables rapid prototyping—turning concepts into physical prototypes within hours. This speed facilitates quicker testing, iteration, and refinement, ultimately bringing products to market faster.

Cost Savings and Material Efficiency

By optimizing design software 3d printing workflows, companies can significantly lower production costs. Precise digital models minimize material waste, reduce labor costs, and eliminate the need for expensive tooling. This economical approach makes 3D printing highly attractive for small batch productions and custom manufacturing.

Customization and Personalization

One of the standout benefits of design software 3d printing is the ability to easily customize designs for individual clients or specific applications. Healthcare, for example, benefits from tailored prosthetics and implants, while fashion and jewelry leverage personalized accessories, all enabled by sophisticated 3D design tools.

Key Features of Leading Design Software 3D Printing Platforms

- Intuitive User Interface: Simplifies complex design processes, making 3D modeling accessible to both novices and experts.

- Parametric Design Capabilities: Allows for easy modifications by adjusting parameters, saving time during iterations.

- Support Structure Optimization: Automates the generation of supports to ensure successful printing of complex geometries.

- Layer Simulation and Visualization: Enables users to preview how objects will build layer-by-layer, identifying potential issues before actual printing.

- Material and Process Compatibility: Supports multiple filament types, resins, and other materials to match project requirements.

- Integration with 3D Printers: Seamless communication with various printer models for streamlined workflows.

- Collaboration Tools: Facilitates team-based projects through cloud sharing, version control, and real-time editing.

Top Design Software 3D Printing Solutions in the Industry

Numerous software options are available, each offering unique features tailored to different user needs. Here are some of the most prominent solutions:

Fusion 360

This cloud-based CAD software by Autodesk combines parametric modeling, freeform design, and simulation tools. Its integrative capabilities streamline the entire product development process, from initial concept to print readiness. Fusion 360 is widely adopted in engineering, hobbyist, and educational sectors due to its versatility and robust features.

SolidWorks

Known for its powerful parametric design environment, SolidWorks offers extensive 3D modeling capabilities. Its integrated simulation tools help predict print failures and optimize designs for 3D printing, making it a favorite among professional engineers and industrial designers.

Ultimaker Cura

Primarily a slicing software, Cura also possesses robust 3D design features compatible with various CAD tools. It excels in support generation, layer preview, and material management, providing a comprehensive solution for 3D printing workflows.

TinkerCAD

A user-friendly, browser-based CAD program suited for beginners. Despite its simplicity, TinkerCAD enables quick prototyping and straightforward design software 3d printing workflows, making it ideal for education and small projects.

Blender

An open-source 3D modeling suite popular for artistic and complex organic designs. Blender’s powerful sculpting and rendering features are increasingly used in design for 3D printing, especially for custom figurines, jewelry, and artistic prototypes.

Best Practices for Effective Design Software 3D Printing Use

- Understand Material Properties: Know the limitations and capabilities of the chosen filament or resin to ensure your design is feasible for printing.

- Design for Additive Manufacturing: Employ design techniques such as generative design, lattice structures, and support-less geometries to optimize material use and print success.

- Validate and Simulate: Use design software 3d printing tools to run simulations, detect potential print failures, and adjust accordingly before printing.

- Maintain File Integrity: Always check for manifold errors, overlapping geometries, and proper scaling to prevent print issues.

- Iterate Rapidly: Leverage cloud collaboration and version control to refine designs iteratively and respond swiftly to testing feedback.

- Stay Updated with Software Enhancements: Continuously explore updates and new features to maximize efficiency and leverage emerging design capabilities.

The Future of Design Software 3D Printing: Trends and Innovations

The landscape of design software 3d printing is dynamic, with ongoing innovations shaping the future of manufacturing. Some key trends include:

- Artificial Intelligence and Machine Learning: Automating complex design optimization, support generation, and failure prediction for smarter workflows.

- Generative Design: Using algorithms to explore vast design spaces, offering innovative geometries that balance strength, weight, and material efficiency.

- Cloud-Based Collaboration: Enhancing remote teamwork, version control, and data management for distributed design teams.

- Integration of Post-Processing and Finishing: Developing software that includes steps beyond printing, such as surface smoothing and assembly planning.

- Sustainability Focus: Supporting eco-friendly materials and processes, promoting waste reduction, and energy-efficient workflows.

Conclusion

In today’s competitive manufacturing and product development environment, mastering design software 3d printing is essential for innovative businesses seeking to stay ahead. These advanced tools empower designers and engineers to create complex, customized, and high-quality objects efficiently and cost-effectively. Whether you're a startup, a large enterprise, or an educational institution, investing in the right design software 3d printing capabilities unlocks endless possibilities for innovation and growth.

At 3DPrintWig.com, we are dedicated to providing the latest insights, tools, and solutions in 3D Printing to help your business excel. Embrace the future of manufacturing with top-tier design software 3d printing, and turn your creative visions into reality today.